S-Keeper 7™ is an emissions analysis system suitable for Type Approved marine engines in compliance with MARPOL Annex VI, NOx Technical Code 2008 and Resolution MEPC.259 (68) 2015 – Guidelines for Exhaust Gas Cleaning Systems designed, built and certified by Tecnova HT.

Thanks to a long-standing partnership with Ignazio Messina & C. Group and as a result of the need to find Suppliers able to offer an analysis system and related professional services tailored to the stringent requirements of the naval industry, Tecnova ht was given the opportunity to test the S-Keeper 7™ system on board a cargo ship of the Group’s fleet.

Thanks to a long-standing partnership with Ignazio Messina & C. Group and as a result of the need to find Suppliers able to offer an analysis system and related professional services tailored to the stringent requirements of the naval industry, Tecnova ht was given the opportunity to test the S-Keeper 7™ system on board a cargo ship of the Group’s fleet.

After carefully examining several ships and their routes, Ro/Ro Container carrier vessel “Jolly Diamante,” IMO number 95788957, with 45,200 tons DWT and a 3,000 TEU capacity, was selected: “Diamante” is equipped with a 2-stroke, 6-cylinder engine that is supplied with typical Heavy Fuel Oil (HFO), covering a total power range of 22,890 kW @108 rpm. After setting sail from the Port of Genoa, the “Jolly Diamante” crosses the Mediterranean, passes through the Suez Canal and then reaches South Africa via the Persian Gulf. On its return voyage, it sails back along the African coast to the Ligurian Sea.

Therefore, for a 2-year period – from September 19, 2016 to October 15, 2018 – the “Jolly Diamante” made 10 voyages with the S-Keeper 7™ system installed on board: 677 testing days during which the vessel covered 154,000 Nautical Miles, tantamount to approximately 285,000 land Kms for a real S-Keeper 7™ sea trials

The technical difficulty of the test lay in the fact that the S-Keeper 7™ system directly analysed combustion emissions from the engine supplied with HFO without any filtration, fume wet scrubber or SCR Selective Catalyst Reduction System – in a nutshell: without any Exhaust Gas Cleaning System.

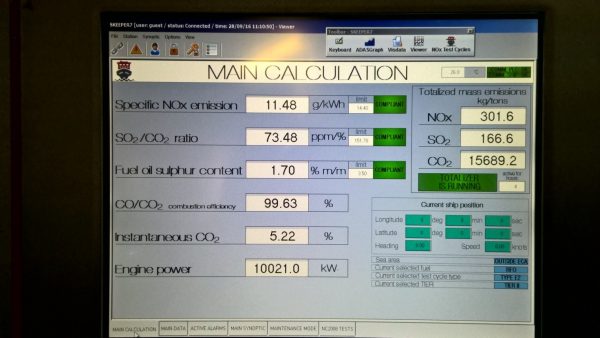

The S-Keeper 7™ system consisted of an in-situ probe in the chimney, a 35-metre heated line and a built-in panel with a sample conditioning section, an analytical section complete with touch-screen display, and validated software.

The continuously analysed components were CO, CO2, SO2, NOx, O2, and their values were acquired, averaged and used to calculate various ratios in compliance with applicable MARPOL regulations, thus making “big data” available to the vessel acquisition system via an RS 485 Bus. Likewise, reports were registered and prepared in accordance with Naval Regulations.

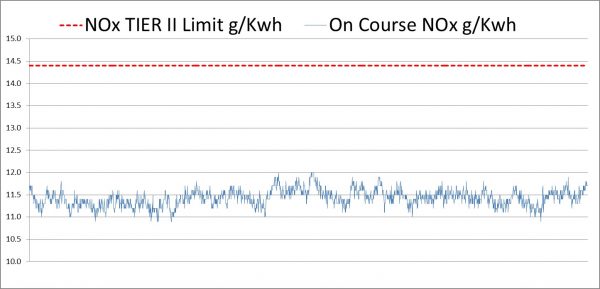

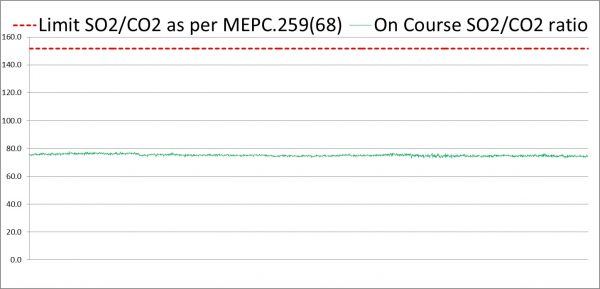

For real-time analytical results that were made available to the ship chief mates, please refer e.g. to the Genoa-Salerno route with 2 dedicated charts:

1) The first chart refers to NOx emissions from the ship chimney compared to the emission limits laid down in MARPOL Annex VI reg.13 TIER II. The unit of measurement is defined as the NOx grams emitted with respect to the engine Power. In addition to detecting NOx pollution, this index allows chief mates on board ships to become aware of engine maintenance levels and any engine performance degradation.

2) The second chart allows the Shipmaster to understand if Sulphur emissions are below the limits provided for in MARPOL Annex VI reg.14 i.e. 3.5% m/m up to 2020, and then 0.5% in the near future. In accordance with MEPC.259(68) Guidelines for EGCS para 1.3, this limit can be verified by calculating the SO2(ppm)/CO2(% v/v) ratio: 3.5% m/m is then reparameterised to 151.7 SO2(ppm)/CO2(% v/v).

The crew on board the “Jolly Diamante” committed themselves to checking system operation on a weekly basis, thus leaving the S-Keeper 7™ virtually maintenance-free, while Tecnova HT’s Milan technical office offered assistance and support remotely during navigation.

When the ship returned to the Port of Genoa, after S-Keeper 7™ sea trials, a complete check-up of the machine was carried out by TECNOVA HT SERVICE staff:

- Probe filter check

- Pneumatic section filter check

- System calibration and validation with certified cylinders pre-integrated into the system

- Analytical data download and interpretation

Needless to say, the on-board test was aimed at solving any technical problems or unpredictable malfunctions during the system ground engineering. Let us see a few examples:

- Using KOH as a technical practice to reduce piston corrosion due to sulphides being present in burnt fuel caused this salt to accumulate in the pneumatic section, subsequently obstructing the piping. Sampling and treating exhaust gases was then improved with different technical measures until an outstanding result was obtained.

- The cargo ship’s temporary summer stops off the Saudi coast led to a surge in the ambient temperature where the S-Keeper 7™ was installed even above the operating limits required for obtaining the type approval, thus temporarily stopping the equipment due to overheating. To face these extreme temperatures, the Tecnova HT team modified the software and instrumental parts jointly with selected Vendors.

“We had previously already installed analysis systems with unsatisfactory results. With S-Keeper 7™ we had to change our minds, as it not only proved to be an accurate and repeatable system, but also one capable of properly operating during entire voyages without the usual heavy routine maintenance.”

Mr. Roberto Boero – Ship management Dept – Technical Manager – Ignazio Messina & C

Thanks to this experience, S-Keeper 7™ has achieved unparalleled reliability and stands out as a valuable tool perfectly completing each Scrubber/EGCS manufacturer’s supply package and allowing Ship Owners to check their EGCS for efficiency with a view to meeting the stringent “Sulphur Cap” 2020 limits while using the same fuel as always. Moreover, thanks to the skilful Software design, Ship Owners can also equip their ships with the new, always available Torque & Thrust meters by Tecnova Ht, thereby using their signals to fully integrate the S-Keeper 7™ system and achieve a real energy efficiency hub.